Pharmaceutical Blister Packaging Solution For Tablets and Capsules

Features

1. The whole machine can be divided into packaging to enter the 2.2 meter elevator and split purification workshop.

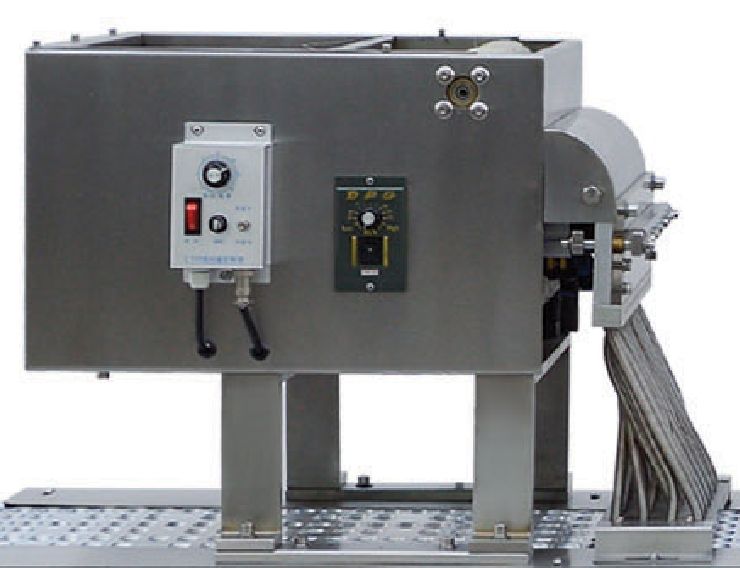

2. The key components are all made of high quality stainless steel and high-grade aluminum alloy material.

3. Novel mold positioning device, It is very convenient to replace the mold with the positioning mold and the whole guide rail ,to meet the general requirements of quick mold change.

4. For an independent station make indentation and batch number separation, so as to ensure the clarity of the indentation and printing (indentation and batch number can also be in a position).

5. The transmission of the machine is isolated from the work area to prevent pollution and facilitate cleaning.

6. The material feeding is controlled by the precision servo motor, the synchronous precision and the length of the stroke are randomly set by the man-machine interface.

7. The heat sealing cylinder is placed under the heat sealing station to reduce machine center, enhance the running stability of the equipment.For the region and the transmission mechanism is completely isolated to prevent pollution, easy to clean up.

8. Aluminum / plastic (hot forming) and aluminum / aluminum (cold forming) General Institutions: Aluminum/Aluminum packing just change the mold and corresponding feeder is OK.

Application

The biggest characteristic of this equipment is using mold positioning design, convenient for customers to replace the mold, reduce debugging time and material cost, the key parts are made of high quality stainless steel and high-grade Aluminum Alloy materials by machining center (CNC), mirror line cutting and other high precision CNC equipment into one processing type, retain the original texture finishing, highlight the noble quality. The transparent protective cover of fine workmanship arc to ensure the safety and the drawing processing of stainless steel cover operation add unlimited style for the overall design, the mechanical products can also bloom artistic charm, the whole process of the details of the pursuit of perfection concept throughout the design and production.

Specifications

|

Model |

DPP88 |

DPP140 |

DPP250 |

DPP350 |

|

|

Cutting Frequency (cutting/minute) (ideal sizes:80*57mm) |

10-30 |

15-45 |

15-45 |

15-45 |

|

|

Max. Forming Area and Depth(mm) |

100*90*15 |

140*110*15 |

250*120*15 |

350*130*15 |

|

|

Adjustable Scope of Travel(mm) |

40-100 |

30-120 |

30-130 |

30-140 |

|

|

Packaging material (I.D.Φ75) |

PVC(mm) |

(0.15-0.4)*110*(Φ300) |

(0.15-0.4)×160×(Φ350) |

(0.15-0.4)×260×(Φ400) |

(0.15-0.6)×350×(Φ400) |

|

PTP(mm) |

(0.02-0.15)*110*(Φ250) |

(0.02-0.15)×160×(Φ350) |

(0.02-0.15)×260×(Φ400) |

(0.02-0.15)×350×(Φ400) |

|

|

Voltage |

220V/1P 50Hz |

380V/3P 50Hz |

380V/3P 50Hz |

380V/3P 50Hz |

|

|

Power(kw) |

4.5 |

5.5 |

8 |

9.5 |

|

|

Air compression(self-prepared) |

0.6-0.8Mpa ³0.3m3/min |

0.6-0.8Mpa≥0.4m³/min |

0.6-0.8Mpa≥0.45m³/min |

0.6-0.8Mpa≥0.6m³/min |

|

|

Recycle water or circulating water consumption (L/h) |

30-50 |

40-80 |

40-80 |

60-100 |

|

|

Overall Dimension (L*W*H)(mm) |

1700*450*1100 |

2400*650*1450 |

2900*750*1600 |

3650*850*1700 |

|

|

Weight (kg) |

300 |

800 |

1200 |

2000 |

|

Products categories

Our Weekly Newsletter

It is a long established fact that a reder will becontent by

the readable of a page when looking.

-

E-mail

-

Phone

-

Whatsapp

-

Top