Products

-

HLSG Series Wet Powder Mixer and Granulator

Features ● With consistent programmed technology ( man-machine interface if option selected ) , the machine can get assured of stability in quality, as well as easy manual operation for convenience of technological parameter and flow progress. ● Adopt frequency speed adjustment to control the stirring blade and cutter, easy to control the size of particle. ● With the rotating shaft hermetically filled with air, it can prevent all dust from compact. ● With a structure of conical hopp... -

High Speed Effervescent Tablet Press with 25mm diameter

26 stations

120kn main pressure

30kn pre pressure

780,000 tablets per hourAutomatic & High Speed production machine capable of effervescent tablets.

-

XZS Series Powder Sifter With Screen Mesh of Different Size

Features The machine consists of three parts: screen mesh in the position of discharging spout, vibrating motor and machine body stand. The vibration part and the stand are fixed together with six sets of soft rubber shock absorber. The adjustable eccentric heavy hammer rotates following the drive motor, and it produces centrifugal force that controlled by the shock absorber so as to meet working requirements, It works with low noise, low power consumption, no dust and high efficiency, a... -

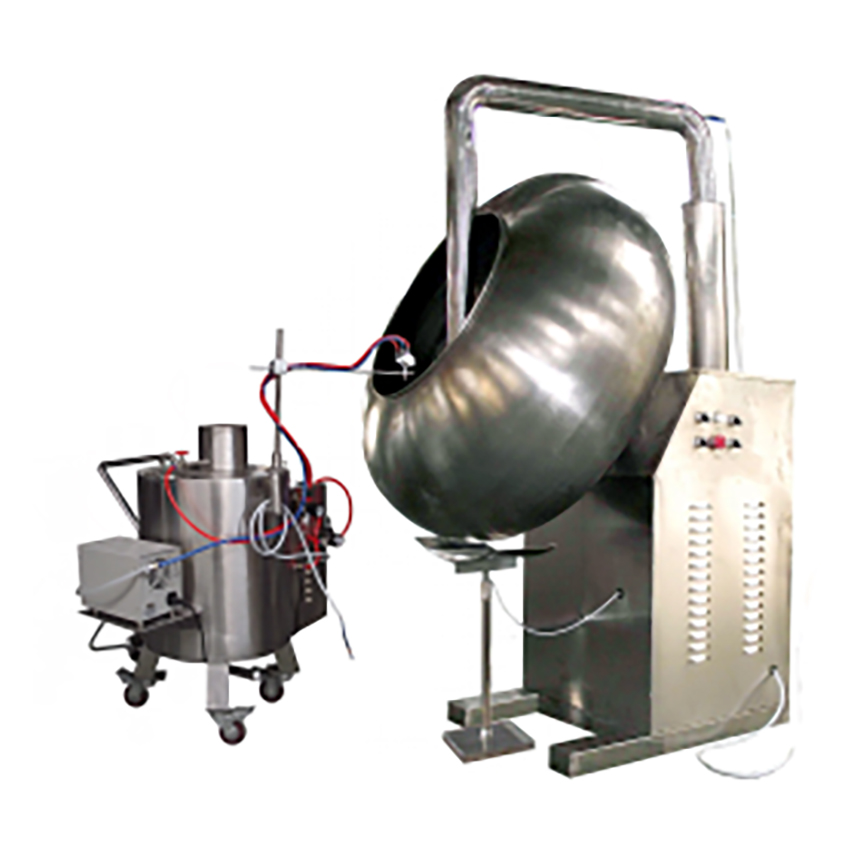

BY Series Tablet Coating Machine

Features ● This coating pot is made of stainless steel, meet the GMP standard. ● Transmission steady, performance reliable. ● Convenient to wash and maintain. ● High thermal efficiency. ● It can produce the technological requirement and regulate coating in one pot of angle. Specifications Model BY300 BY400 BY600 BY800 BY1000 Diameter of pan (mm ) 300 400 600 800 1000 Speed of Dish r/min 46/5-50 46/5-50 42 30 30 Capacity (kg/batch ) 2 ... -

BG Series Tablet Coating Machine

Specifications Model 10 40 80 150 300 400 Max.Production capacity(kg/time) 10 40 80 150 300 400 Diameter of Coating Drum(mm) 580 780 930 1200 1350 1580 speed range of Coating Drum(rpm) 1-25 1-21 1-16 1-15 1-13 Range of Hot Air Cabinet(℃) ordinary temperature-80 Power of Hot air Cabinet Motor(kw) 0.55 1.1 1.5 2.2 3 Power of Air Exhaust Cabinet Motor(kw) 0.75 2.2 3 5.5 7.5 Machine overall si... -

SZS Model Uphaill Tablet De-duster

Features ● Design of G.M.P; ● Speed and amplitude adjustable; ● Easily operating and maintaining ; ● Operating reliably and low noise. Video Specifications Model SZS230 Capacity 800000(Φ8×3mm) Power 150W De-dusting distance (mm) 6 Maximum diameter of the suitable tablet (mm) Φ22 Power 220V/1P 50Hz Compressed air 0.1m³/min 0.1MPa Vacuum (m³/min) 2.5 Noise (db) <75 Machine size (mm) 500*550*1350-1500 Weight... -

Tablet De-duster & Metal Detector

Features 1) Metal detection: High frequency detection (0-800kHz), suitable for detecting and removing magnetic and non-magnetic metal foreign objects in tablets, including small metal shavings and metal mesh wires embedded in drugs, to ensure drug purity. The detection coil is made of stainless steel material, completely sealed internally, and has high precision, sensitivity, and stability. 2) Sieve dust removal: effectively removes dust from tablets, removes flying edges, and raises the... -

HRD-100 model high-speed tablet deduster

Features ● The machine is designed to meet GMP standard and entirely made of stainless steel 304. ● Compressed air sweep off the dust from engraving pattern and surface of tablet within a short distance. ● Centrifugual de-dusting makes the tablet de-dusting efficiently. Rolling de-burring is a gentle de-burring which protect the edge of tablet. ● The static electricity on surface of tablet/capsule can be avoided due to non-brushed airflow polishing. ● Long de-dusting distance, dedusting and d... -

CFQ-300 Adjustable Speed Tablets De-duster

Features ● Design of G.M.P. ● Double layers screen structure, separating tablet& powder. ● V-shape design for the powder-screening disk, polished efficiently. ● Speed and amplitude adjustable. ● Easily operating and maintaining. ● Operating reliably and low noise. Video Specifications Model CFQ-300 Output(pcs/h) 550000 Max. Noise(db) <82 Dust Scope(m) 3 Atmospheric pressure(Mpa) 0.2 Powder supply(v/hz) 220/ 110 50/60 Overall Siz... -

Metal Detector

Pharmaceutical tablet production

Nutritional and daily supplements

Food processing lines (for tablet-shaped products) -

GL Series Granulator for Dry Powder

Features Feeding, pressing, granulation, granulation, screening, dust removal device PLC programmable controller, with a fault monitoring system, to avoid pressing wheel locked rotor, fault alarm and automatically exclude in advance With the information stored in the control room menu, convenient centralized control of technological parameters of different materials Two types of manual and automatic adjustment. Specifications Model GL1-25 GL2-25 GL4-50 GL4-100 GL5... -

Magnesium Stearate Machine

Features 1. Touch screen operation by SIEMENS touch screen; 2. High efficiency, controlled by gas and electricity; 3. Spray speed is adjustable; 4. Can adjust the spray volume easy; 5. Suitable for effervescent tablet and other stick products; 6. With different specification of spray nozzles; 7. With a material of SUS304 stainless steel. Main specification Voltage 380V/3P 50Hz Power 0.2 KW Overall size(mm) 680*600*1050 Air compressor 0-0.3MPa Weight 100kg